Home page > Industries

Industries

ProjetoPack has helped several industries for more than a decade and half, in Brazil and overseas, in improving their performance and costs. Get to know the main sectors where we operate:

The converting industries for flexible packaging, labels and tags suffer from the continuous cooling of their profit margin. The number of print runs decreases, while the sophistication of the arts, the demand of customers and the segmentation of products increase. Being efficient and effective in production (especially in times of adjustment), buying well and assertively your inputs and tools and making good use of your industrial park are vital skills to face this challenging market.

We help various industries, in Brazil and overseas, in improving their industrial and cost performance, being recognized by our clients - since small industries to the large multinationals - as a great problem solver in the factory floor and a great mentor in the path of a World Class OEE, especially in the printing area.

Brand owners face three vital challenges everyday: ensuring the integrity of their brand in several platforms (signaling, various packaging, print ads, outdoor media, etc), choosing suppliers that are competent in costs and innovation, and purchasing, in an intelligent way, print material - especially packaging and labels - which are an intrinsic part of their products and main communication vehicle of their brand.

ProjetoPack has helped brand owners to perform in these three themes, generating tangible and intangible expressive gains to clients.

With the advancement of flexible packaging, the corrugated cardboard and card packaging industry has to reinvent itself every day. Part of this reinvention is to print with extremely high quality, reduced batches, to the lowest cost possible - something that is difficult many times, due to the culture and vices in the factory floor and the lack of technical qualification of the operational team.

ProjetoPack has helped tens of packaging converting industries to earn the required knowledge to transform their operation in a reference of productivity, both in analogical printing (mostly flexographic) and in new digital technologies.

The glass and hard plastic packaging industries (blown, injected or thermoformed) have very difficult surfaces for direct printing. However, indirect decoration processes proliferate and improve, such as heat transfer, shrink sleeve, sticker label, in-mold label and in-mold decoration.

ProjetoPack has helped several industries in enhancing the technical quality of their printing in these critical materials, without, however, increasing costs or decreasing the productivity of the factory.

The paradigm now is of gaining efficiency and reducing the consumption of inks, which considerably increases the cost of print ceramics.

ProjetoPack has increasingly specialized in the several digital systems that exist in the industrial printing sector, in order to help its clients to profit as much as possible from their lines, at competitive costs.

The furniture and corner tape industries face various technical challenges in printing (usually knowing as painting): the first is printing with an increasingly high quality, more natural and organic patterns and textures. The second is to improve the efficiency of the lines and reducing the rework amount, a critical and very common problem to most of the companies. And, lastly, to reduce the production cost in painting, especially felt at the high consumption of primer, ink and varnish.

ProjetoPack has helped several clients in this sector, which includes industries that hold a prominent position in the national furniture and corner tape industry.

Textile and soft signage industries, as well as the ceramics sector, are moving to digital systems. This new reality requires more technical entertainment of pre-printing and printing, color management and process control - something that the most rudimentary experience of “painting” didn’t require with the same intensity.

ProjetoPack has helped, more recently, industries from these sectors to acquire the required knowledge to improve profits in the printing operations.

One of the most sectors mostly in need is stamping. Enamelers and engravers (embossing or paper imprinting, calendering, etc) produce very slowly and, several times, outside the standard. The printing of textures itself is not satisfactory and there is also the premature wear of special cylinders, which are also very expensive.

ProjetoPack has helped stamping companies to reduce the re-engraving costs of special cylinders (through adequate process control, handling, storage and cleaning), save on inks and increase the speed of the printing and stamping lines.

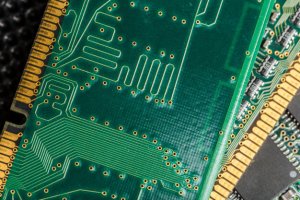

One of the emerging markets in the printing industry is the one of printed electronics. It encompasses several interesting sectors, such as the printing of circuits, batteries and photovoltaic (solar) panels.

ProjetoPack is one of the only consultancy companies in printing of the world to operate in the new and technological sector, with several success cases in Brazil and overseas. The production of electronics does not allow failures in printing - it is literally “zero error”, once each square meter out of specification means an extremely high financial loss, some hundreds or even thousands of dollars. In some cases, such as printing of solar panels, even the tests with the print product may affect its characteristics.

The visual communication printing companies (large formats) produce from simple prints to the most sophisticated (and expensive) adhesive substrates, such as the film for vehicle wrapping. Keeping a profitable operation, in the midst of a gigantic competition, demands, among many aspects, an accurate work of color management and input saving, especially inks.

ProjetoPack has helped tens of visual communication printing companies, inserted in several sectors, to print with more efficiency at reduced costs.

One of the most affected sectors in the printing industry with the rise of the internet, social media, mobile and other electronic devices that allow online reading (e-readers, for example) is the publishing and commercial offset printing, plain or rotary. Although the traditional offset printing has a lot of available reading and a lack of workforce relatively smaller than other printing systems, there is still much to do in a printing company to productively print. OEE in printing lines in Brazil is still very low, in relation to the same lines overseas, which print products with printing numbers and complexity that are relatively the same.

ProjetoPack has helped many of these printing companies, through the implementation of a full program of lean production designed especially for offset printing companies, to achieve a new level of productivity in printing.

Other sector that is extremely sensitive to error is the one of safety prints, which presents also a particular challenge: most of the printers has hybrid technology, gathering in the same equipment different printing systems. The lack of a careful control of processes may result in the generation of trimmings in alarming levels.

ProjetoPack has contributed a lot with the printing companies that operate in this sector, to reduce, waste, adjustment times and costs resulting from the nature of these prints that are so complex and full of finishings that are also expensive (holography, coldfoil, hot stamp, cast and cure, paper imprinting, lases scoring, etc).

Any company that puts ink over a substrate to reproduce one or more copies from an original needs color management, control in receiving input, process control and qualification of the line operators.

ProjetoPack is able to help companies to print better and at more competitive costs in practically any analogical process (rotogravure, flexographic printing, offset, lithography, pad printing, intaglio, serigraphy, dry offset, letterpress, etc.) and digital (inkjet D.O.D or continuous flow, digital offset sublimation and many other).

Manufacturing industries of printing machines, substrates, plates and cylinders, plate sleeves, anilox, blades, double-sided tapes, accessories, inks and solvents and an infinity of other material - want help to evaluate new products or services, follow tests, understand or even identify new market niches and even contract our team for the start-up of a new equipment in a client.

ProjetoPack has provided these services to hundreds of national and multinational companies, being a reference and a strategic partner to all of them in the printing sector.